vickers and rockwell hardness test|vickers hardness to mohs scale : manufacturer The three most well known and widely used hardness tests for metals today are Brinell, Rockwell, and Vickers. Here are the basic differences explained. 713-827-0700 WEBDownload Now. The above link will download the content sent to you, plus a µTorrent client if you do not already have one. If you prefer to use a different bittorrent client, you can use the magnet link. Have the bundle torrent. Or the proxy torrent link.

{plog:ftitle_list}

Resultado da Virginia Fonseca ReidaPutaria7. 1 131,1K. Virginia Fonseca Twerk for BBC CUMTRIBUTE77. 1 64,9K. Virginia Fonseca Cumtribute PMV babecock😈🤤 CUMTRIBUTE77. 1 51,5K. Virginia Fonseca babecock Cumtribute compilado 🤤 CUMTRIBUTE77. 3 20,5K. CUM TRIBUTO VIRGINIA FONSECA .

The Rockwell hardness test uses a simple mechanical load application, while the Vickers hardness test uses an optical measurement method. The Rockwell hardness test is .There are three principal standard test methods for expressing the relationship between hardness and the size of the impression, these being Brinell, .1. Vickers Hardness Test. This method uses a diamond pyramid indenter with a square base. The indenter is pressed into the material with a specific load, and the size of the indentation is . The three most well known and widely used hardness tests for metals today are Brinell, Rockwell, and Vickers. Here are the basic differences explained. 713-827-0700

Vickers Hardness Test. Making use of a diamond indenter, the Vickers hardness test is done with less force and more accuracy than the Brinell test. By magnifying the surface of a metal, this test can target specific .

What is the Difference between Rockwell and Vickers Hardness Test? 1. Testing Principle. 2. Indentation Shape. 3. Load Ranges and Accuracy. 4. Measurement. 5. Materials. 6. Accuracy and Precision. 8. Test Result . The most common methods used for testing the hardness of metals are Rockwell, Brinell, Vickers, and Knoop. Each of these methods employs different indenters and loads to measure the material’s resistance to .

Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). The most . ISO 6507: This standard contains the details for the Vickers hardness test in metallic materials. ISO 6508: This standard is very similar to ASTM E18, as it deals with the Rockwell hardness tests, both superficial and .

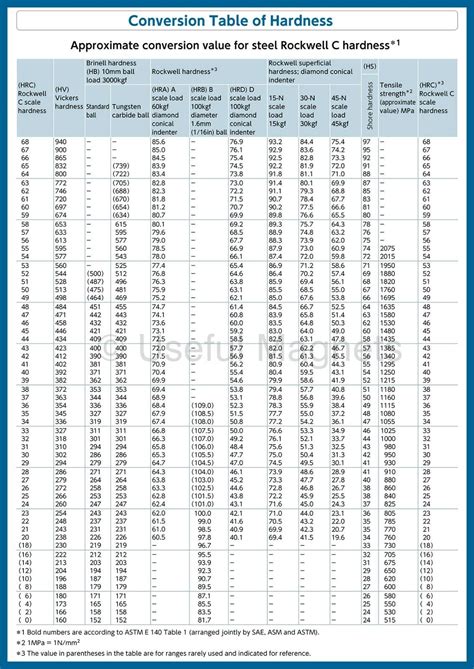

vickers hardness to rockwell conversion

A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .The Rockwell hardness test is applied globally for the application of an experimental indentation hardness test. The Rockwell test is a quick process, very cost-effective, and non-destructive test (causing only minor indentation on the specimen material). The Rockwell hardness test is a simple process that is why it can be performed by anyone . Variants on the Rockwell hardness test procedure are used depending on the material and strength of a part. The most common Rockwell variants include: . It’s also critical to specify the correct load for Knoop tests because too-light loads could produce falsely high hardness readings. For Vickers tests, too-light loads create too-small .

With the Brinell hardness test, a carbide ball is pressed into the material. The indentation surface serves as a measure of the hardness. Vickers hardness te.

The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can be also used as a microhardness test method , which is mostly used for small parts, thin sections, or case depth work.

The Vickers Hardness test (ISO 6507) is used to characterize hardness of various solid materials (metals, ceramics, etc.). A diamond pyramid is pressed against the solid with a certain normal load and the hardness is calculated based on the imprint left on the surface. . In contrast with Rockwell and Brinnell hardness techniques, the pyramid .Easily convert Vickers Hardness to Rockwell with our detailed guide. Learn about both testing methods, explore the conversion process, and use our conversion table for accurate results. . Vickers hardness testing is frequently used, but Rockwell hardness values may be needed for specific client requirements or material certifications. 3.Steel Hardness Conversion Table. This table shows approximate hardness of steel using Brinell, Rockwell B and C and Vickers scales. These conversion charts are provided for guidance only as each scales uses different methods of measuring hardness. The right hand column show an approximate equivalent tensile strength.The Rockwell hardness test is less affected by surface rough-ness compared to other methods such as the Vickers or Brinell tests. It can provide reliable hardness measurements even on . The Vickers hardness testing method offers advantages such as a small indentation size, accurate hardness measurements,

The three most widely used today are Brinell, Rockwell, and Vickers. Brinell Hardness Test. Proposed by J.A. Brinell in 1900, the Brinell Hardness Test was the first standardized hardness test to be used, and it is still widely used today. In this test, the metal surface is indented with a 1 to 10 mm diameter steel, or most recently, a tungsten . What is Rockwell hardness test? The Rockwell hardness test is a hardness measuring method using Rockwell scale to measure the depth of penetration of an indenter under a large load on the surface. Rockwell scale has different scales denoted by a single letter. The higher the number in the scales means the harder is the material.A Vickers hardness testing machine was employed to determine the hardness differences of all the rolled strip specimens in the thicker, thinner, and transition zones by applying a load of 1 . Rockwell hardness testing can be carried out to either ISO 6508-1 or ASTM E 18. Conversion tables are available to convert between Vickers, Brinell and . The NG-1000 - Micro Vickers and Knoop Hardness tester is the most advanced hardness tester for accurate measurements and ease of use. The NG-1000 - Micro Vickers and Knoop Hardness tester comes standard with a motorized turret and is available in three (3) different configurations to suit all requirements.

A standardized test procedure used to determine the hardenability of steel, the Jominy test (End Quench Test) can be performed using either the Vickers or Rockwell hardness test method. When selecting which to use, you should . Rockwell Hardness Test. Developed to provide a less destructive alternative to the Brinell test, this differential-depth method eliminates the errors associated with mechanical imperfections. . Making use of a diamond .The Rockwell hardness test and Vickers hardness test are two commonly and widely used techniques among the many hardness testing methods. They can test different types of materials. Rockwell and Vickers hardness tests adopt . Introduction of Rockwell hardness Rockwell hardness is an index to determine the hardness value by the depth of indentation plastic deformation, with 0.002 mm as a hardness unit, expressed as HR. Using different indenters and different test forces in the Rockwell hardness test will produce different combinations (HRA t

The Rockwell hardness test is based on the indentation depth caused by a diamond or a ball indenter under different loads. There are two main scales used in the Rockwell test: the Rockwell HRC scale (uses a diamond cone indenter) for harder materials and the Rockwell HRB scale (uses a ball indenter) for softer materials. . The Vickers .

Standardized Testing: Vickers hardness testing is commonly used in standardized testing methods, making it suitable for comparing hardness values across different materials. Macrohardness Testing: While primarily a microhardness test, Vickers hardness testing can also be adapted for macrohardness testing of larger samples.

The Vickers hardness test can measure the entire range of hardness values as it can evaluate all the materials and samples used for the test, whether they are soft or hard in texture. . The speed of the method is not very efficient relative to Brinell or Rockwell hardness test. Apart from the time which is consumed for the preparation of the .High Rockwell hardness numbers represent hard materials and low numbers soft materials. d 2 www.wilsoninstruments.com Fundamentals of Rockwell Hardness Testing Like the Brinell, Vickers, Knoop, Scleroscope and Leeb tests - all of which fall in the general category of indentation hardness tests - the Rockwell test is a measure of the resistance . The Rockwell hardness test involves applying a sequence of loads to the material and measuring the depth of the resulting indentation, which indicates the material’s hardness. . The Vickers hardness test is a versatile and precise method suitable for a wide range of materials, from soft metals to hard ceramics, and is especially valuable .

The Vickers hardness test method, also referred to as a microhardness test method, is mostly used for small parts, thin sections, or case depth work. The Microhardness test procedure, ASTM E-384, specifies a range of light loads using a diamond indenter to make an indentation.The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a Rockwell test. The Rockwell test is generally easier to perform, and more accurate than other types of hardness testing methods .

Superficial Rockwell Hardness Test Blocks - ASTM E-18 and ISO 6508 use, on the other hand, such kinds of penetrators: N Diamond, 1/16" Ball, 1/8" Ball, . Vickers Hardness Test is a flexible hardness test technique that is used to measure both macro and microhardness. It is appropriate for a variety of applications and materials and has a wide . Vickers Hardness Test. The Vickers test was developed in the 20s of the XX century by Robert L. Smith and George E. Sandland, who worked for Vickers Ltd. The method uses an indenter tip that is a regular tetrahedral diamond pyramid. This alternative to the Brinell test for measuring the hardness of materials facilitates the measurement because .

Reciprocating Friction Tester warehouse

Rubber vulcanizing Tester warehouse

Resultado da Sayen é um filme dirigido por Alexander Witt com Rallen Montenegro, Arón Piper. Sinopse: Uma mulher indígena Mapuche descobre uma .

vickers and rockwell hardness test|vickers hardness to mohs scale